Pet Food Machinery: Dry Pet Food

SEH

The Sanitary Extruder Hood (SEH) is used in the manufacture of dry, cereal based foods produced continuously on a cooker extruder, commonly known as kibble.

The SEH has been designed by Frazer-Nash to meet the latest global hygiene requirements for foods and complies with the FDA guidelines and the European regulation for materials in contact with foods.

The kibble process uses the client’s cooker extruder to mix, cook and pressurise the kibble recipe so that it can be extruded through a die plate. As the food leaves the die plate it is cut into small pieces via a rotary knife and carried away on a high velocity clean air stream. Clean air is delivered under pressure into the cutting chamber and carries the cut food vertically upwards allowing the soft product to flash excess moisture into the air stream without sticking together or deforming under its own weight. The food is discharged from a cyclone separator into a drying oven to reach final moisture content.

The Frazer-Nash SEH is the only CNC machined hood on the market offering unparalleled precision of finish to ensure repeatable reliable use over an extended life time.

SEV

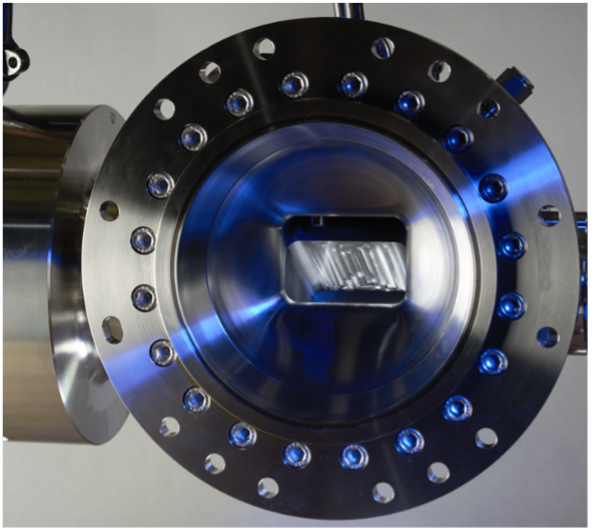

The Sanitary Extruder Valve (SEV) is used to control the specific mechanical energy (SME) in extruder barrels. It is a new solution designed to meet the exact needs of customers. The clean design is optimised for cleanliness and is easy to install, operate and maintain. It is engineered for a long, trouble-free operating life. It provides the precise control of temperature across the die face and allows you to minimise clean-out times.

The kibble process uses the client’s cooker extruder to mix, cook and pressurise the kibble recipe so that it can be extruded through a die plate. As the food leaves the die plate it is cut into small pieces via a rotary knife and carried away on a high velocity clean air stream. Clean air is delivered under pressure into the cutting chamber and carries the cut food vertically upwards allowing the soft product to flash excess moisture into the air stream without sticking together or deforming under its own weight. The food is discharged from a cyclone separator into a drying oven to reach final moisture content.

The Frazer-Nash SEH is the only CNC machined hood on the market offering unparalleled precision of finish to ensure repeatable reliable use over an extended life time.

BCB

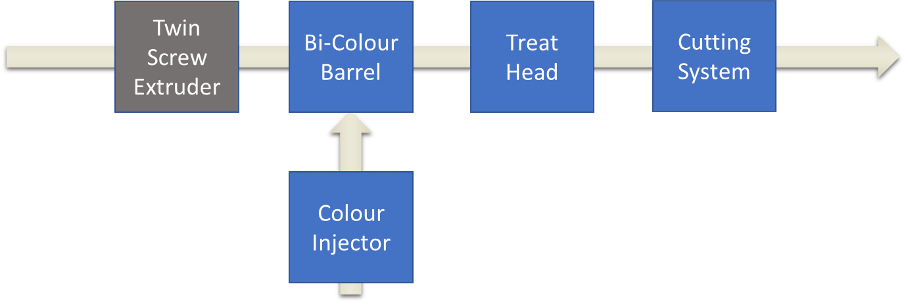

The Bi-Colour Barrel splits the output of a twin screw extruder into two separate channels allowing mixing of colour into each channel.

The BCB has a matched diameter with twin screw extruder, dual output for treat or kibble production and is driven by existing extruder shafts.

The Liquid colour mixing system injects up to 1% liquid into extrudate. It mixes hand weighed colour powders in water to form fully dissolved solutions at room temperature. It then transfers ready mixed and soluble colours (or water) to 25 litre dosing vessels.

Guillotine

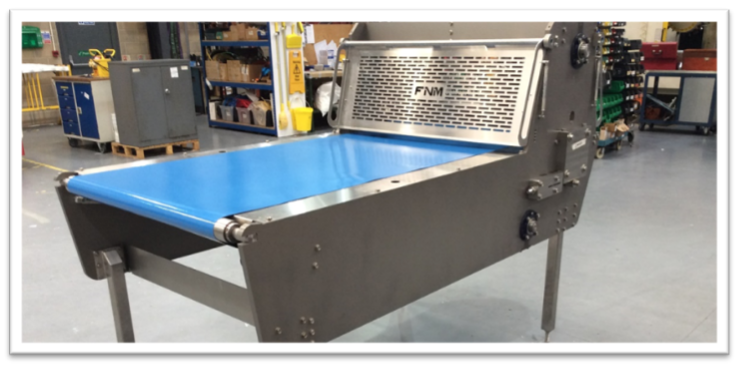

Our Guillotine is designed to safely aid in the quick production of pet treats, giving a consistent cut to the product.

Our high speed guillotine, offers a maximum cutting speed of 180 cuts per minute. The cutting system uses an 820mm ultra-sonic, hardened stainless steel blade, that can cut depths up to 50mm. The reciprocating action of the blade prevents product deformation during the cutting process.

Get in touch

Contact Frazer-Nash Manufacturing for a discussion of your specific requirements.

Call us on +44 (0)1730 230 340 or submit your enquiry using this form to request a call back.